Agriculture

September 11, 2024

KSNM Direct Paddy Seeder

Read SolutionImplemented by

KSNM

Updated on February 2, 2024

·Created on August 15, 2022

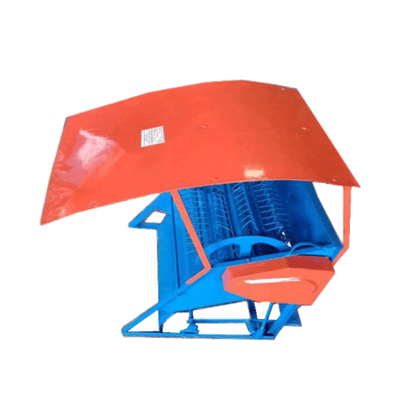

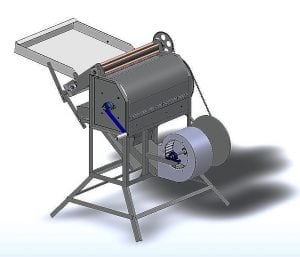

Paddy thresher is designed to have loop type threshing drum with a supporting frame and is used for manual threshing.

The Paddy thresher is designed for manual threshing of rice. It consists of a loop type threshing drum which is supported on a frame. It contains two cast iron gears which quadruples the speed obtained from treadle movement of the cylinder to about 400 rpm. Paddy threshing is done by holding the paddy stalks with grain against the death of the revolving cylinder.

Target SDGs

SDG 2: Zero Hunger

SDG 9: Industry, Innovation and Infrastructure

Market Suggested Retail Price

$71.71

Market Suggested Retail Price (Secondary Currency)

4,950.00

Target Users (Target Impact Group)

Household, Community, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

The product is distributed by the manufacturer and dealers.

Regions

Asia

Manufacturing/Building Method

The product is mass manufactured in India

Intellectural Property Type

Trademark

User Provision Model

Users can obtain this product directly from manufacturer or buy it from Indiamart.

Distributions to Date Status

Unknown

Feedstock type

Paddy

Feedstock rate (kg/hr)

140

Manual or motorized

Manual

Energy requirement (W)

None

Portable or stationary

Portable

Design Specifications

The product has been designed to thresh rice manually. Fitted with two cast iron gears, the speed obtained from treadle movement is quadrupled to 400 rpm. Paddy threshing is done by holding the paddy stalks with grain against the teeth of the revolving cylinder. The machine is pedal operated to make cylinders rotate.

Technical Support

There is no technical support provided and users are expected to maintain the product on their own.

Replacement Components

Bearings, teeth on cylinder

Lifecycle

Unknown

Manufacturer Specified Performance Parameters

Designer specified performance targets include: speedy performance, durable and strong structure, easy to use and maintain.

Vetted Performance Status

Unknown

Safety

Users of the implement should be cautious of the teeth on the rotating drum and injuries from flying chuff and seeds.

Complementary Technical Systems

None

Academic Research and References

Kamal-Raj, et al., 2010, A Comparative Study on the Manual Beating of Paddy and Manually Operated Paddy Thresher on Farm Women. Human Ecology, 32(3): 183-187

Singh, K.P. et al., 2008, Optimization of machine parameters of a pedal-operated paddy thresher using RSM. Research Paper: RD—Rural Development, 100:591–600

This paper details testing of manual paddy threshers

Compliance with regulations

ISO certified 9001:2008

Agriculture

September 11, 2024

Implemented by

KSNM

Agriculture

February 6, 2024

Implemented by

SAYeTECH Ltd

Agriculture

September 18, 2024

Implemented by

Alvan Blanch

Agriculture

September 19, 2024

Implemented by

Amaragri

Agriculture

February 6, 2024

Implemented by

MIT D-Lab

Agriculture

February 6, 2024

Implemented by

Compatible Technology International

Agriculture

February 6, 2024

Implemented by

Australian Centre for International Agricultural Research

Agriculture

August 29, 2024

Implemented by

Weifang Public Machinery Co., Ltd.

Agriculture

June 11, 2024

Implemented by

Honeycomb

Agriculture

June 12, 2024

Implemented by

Delair Tech

Have thoughts on how we can improve?

Give Us Feedback