Agriculture

June 23, 2024

AgRover

Read SolutionImplemented by

MAPS (Mobile Agricultural Power Solutions)

Updated on February 16, 2024

·Created on October 13, 2020

Phytoponics designs and manufactures hydroponic growing systems which utilize deep water culture, meaning plant roots are fully submerged.

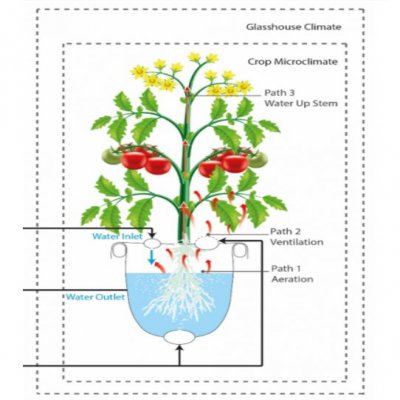

Phytoponics designs and manufactures deep water culture hydroponic systems. Deep water culture refers to a method of growing where plant roots are fully submerged in oxygenated water with no soil or substrate. The hydroponic systems are designed for commercial producer growers, and specifically for nutrient intensive vine crops, soft or exotic fruits, and high value crops such as medical grade cannabis. The root zone of the crops can be monitored to ensure the correct oxygen and nutrient levels. The materials used in the system are all multi-use and recyclable.

Target SDGs

SDG 2: Zero Hunger

Target Users (Target Impact Group)

Small and Medium-sized Enterprises

Distributors / Implementing Organizations

Phytoponics is contracted by commercial produce farmers in Europe to design an appropriate hydroponics system for that grower.

Regions

Europe

Countries

United Kingdom

Manufacturing/Building Method

Phytoponic systems are currently manufactured in an R&D facility in the Stockbridge Technology Centre in Yorkshire, England.

Intellectural Property Type

Patent

User Provision Model

Phytoponics is contracted by commercial produce farmers in Europe to design an appropriate hydroponics system for that grower.

Distributions to Date Status

Unknown

Design Specifications

Phytoponic systems are hydroponic growing systems that utilize deep water culture, meaning the roots of a plant are fully submerged in water without the use of any soil or substrate. Each Phytoponic system is specially designed for each client. The plant roots are submerged in a homogenous nutrient solution which can be controlled by the user to ensure the correct nutrients, pH, oxygen aeration, and temperature for the plant. These controls allow the user to introduce certain stressors to the plant to influence crop physiological traits.

Technical Support

Technical Support is provided by the manufacturer.

Replacement Components

The grow system is specially designed to suit the needs of the user.

Lifecycle

Unknown

Manufacturer Specified Performance Parameters

The manufacturer specifies their hydroponic systems are specifically designed for nutrient-intensive vine crops, soft/exotic fruits, and high-value crops. They also specify that their systems enhance the yield and quality of the produce grown in their systems and that their product is more eco-friendly than hydroponic systems that use substrate.

Vetted Performance Status

Testing performed by the manufacturer in conjunction with the European Study Group with Industry (ESGI), the University of Bath, and the University of Bristol found that the company's Hydrosac system allows for the infiltration and mixing of nutrients using inlet flow and bubble mixing.

Safety

No known safety hazards are related to this product.

Complementary Technical Systems

A power source and fertilizers are required to use this product.

Academic Research and References

Dixon, A., 2018, Optimisation of Fluid Mixing in a Hydrosac© Growing Module, ESGI 138, England.

De Bernardi, P. and Azucar, D., 2020, Innovation for Future Proofing the Food Ecosystem: Emerging Approaches, Innovation in Food Ecosystem, pp. 105-134.

Segarra, J., Jorro, J., Merloni, E., and Duarte, A., 2019, The Transformation of Citrus Waste in Bioproducts, Manual for Agricultural Vet Teachers.

Compliance with regulations

Unknown

Other Information

Phytoponics' Hydrosac design was awarded the Spark Award by the Design Council in 2017

Phytoponics Co-founder Adam Dixon was selected to become a United Nations Young Champion of the Earth in 2017.

Phytoponics secured £500,000 to scale commercial trials to manufacture

Phytoponics Testing and Optimisation of Fluid Mixing in a Hydrosac

Agriculture

June 23, 2024

Implemented by

MAPS (Mobile Agricultural Power Solutions)

Agriculture

February 3, 2024

Implemented by

Barrix

Agriculture

August 21, 2024

Implemented by

Claphijo Enterprises

Agriculture

August 29, 2024

Implemented by

Futurepump Ltd.

Agriculture

January 19, 2024

Implemented by

ICU/Desert Tulip/Groasis

Agriculture

January 22, 2024

Implemented by

Proximity Designs

Agriculture

June 23, 2024

Implemented by

Planet Labs

Agriculture

January 19, 2024

Agriculture

September 19, 2024

Implemented by

Hydroponics Africa

Agriculture

September 18, 2024

Implemented by

Project Support Services (PSS)

Have thoughts on how we can improve?

Give Us Feedback