Agriculture

December 18, 2024

Breezergy Micro Wind Turbine

Read SolutionImplemented by

SkyWind Energy GmbH

Updated on January 24, 2024

·Created on May 27, 2016

The Piggott Axial Flux Alternator Wind Turbine is an open source wind turbine that can be built by end users.

The Piggott Axial Flux Alternator Wind Turbine is an open source wind turbine technology (construction instructions available in Hugh Piggott’s manual, How to Build a Wind Turbine) that aims to use local materials to manufacture wind turbines of varying sizes and energy outputs.

Target SDGs

SDG 7: Affordable and Clean Energy

SDG 8: Decent Work and Economic Growth

Market Suggested Retail Price

$1,500.00

Target Users (Target Impact Group)

Household

Distributors / Implementing Organizations

Hugh Piggott's manual is available for purchase online to all end users for personal construction of the turbine.

Competitive Landscape

Direct competitors include Qr6 Vertical Axis Wind Turbine, Rutland FM910-4 Furlmatic Windcharger, and Bornay Inclin 600.

Regions

Worldwide

Manufacturing/Building Method

Turbines are individually manufactured

Intellectural Property Type

Open-source

User Provision Model

The Piggott Turbine can only be manually constructed by following the directions outlined in Hugh Piggott's open source book A Wind Turbine Recipe Book.

Distributions to Date Status

Since the product is open source, the exact number of constructed turbines is unknown.

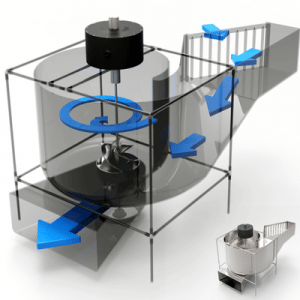

Description of system

Turbine

Start up windspeed (m/s)

3 m/s

Power output, min (W at m/s)

500 W at 12 m/s

Power output, max (W at m/s)

2,000 W at 12 m/s

Height of system (m)

Unknown

Radius of movement (m)

Unknown

Description of control system

Furling tail for overspeed

Design Specifications

The Piggott Turbine has two types of designs - 2F and 4F Turbine design.

For the 2F design:

For the 4F design:

For the structure turbine design:

The blades are hand carved from softwood. The alternators are comprised of neodymium magnets mounted onto laser-cut steel magnet discs and stator is comprised of hand-wound copper coils. The mounting is comprised of bearings to mount the blades and magnet discs, steel frame to attach the stator and bearing to a tower and a tail boom mechanism.

Further details of the design can be found in the handbook.

Technical Support

All technical information is available in the instruction manual. The owner of the design can be contacted through his email or his phone number.

Replacement Components

All the components for construction are common manufacturing materials and parts that are most likely available in country, or can be purchased from online wind turbine suppliers.

Lifecycle

Lifetime, disposal, and warranty information is unavailable and dependent on individual manufacturing of the product.

Manufacturer Specified Performance Parameters

The designer's aim was to provide access to electricity in rural areas.

Vetted Performance Status

The testing is usually done by the owner of Piggott Wind Turbine, Hugh Piggott, and through Solar Energy International (SEI), a seminar was conducted. The product was tested for power output at varying wind speeds, which varies based on blade size.

Safety

Grinding, sanding, drilling, welding are dangerous practices and should be performed with caution. The construction involves several dangerous tasks and some materials may be sharp or toxic, so caution is required during construction. The manual discusses potential hazards in depth. There are no known hazards during the windmill's operation.

Complementary Technical Systems

Unknown

Academic Research and References

The Piggott Turbine – Wind Empowerment. 2019. Wind Empowerment – Wind Empowerment. November 6, 2019.

Hugh Piggott. n.d. A Wind Turbine Recipe Book. www.scoraigwind.com.

The Piggott Wind Turbines – Background Information. n.d. PureSelfMade.

Hugh Piggott Wind Turbine Components» v3 Power. n.d. V3power.co.uk.

Piggott, Hugh. 2003. How to Build a Wind Turbine. scoraigwind.com. Hugh Piggott.

Hugh Piggott. 2013. Nice Exploded Diagram of 1200 Recipe Turbine | Hugh Piggott’s Blog. scoraigwind.com.

Contact | Hugh Piggott’s Blog. n.d. scoraigwind.com.

Forcefield. 2004. Notes on Building and Testing Hugh Piggott’s Axial Flux Wind Generator. zetatalk11.com. Guemes Island, WA: Forcefield.

Compliance with regulations

Unknown

Evaluation methods

The manufacturer used both laboratory research and field testing to evaluate technology in terms of power output and other performance indicators.

Agriculture

December 18, 2024

Implemented by

SkyWind Energy GmbH

Agriculture

December 18, 2024

Implemented by

VWT Power (QuietRevolution)

Agriculture

December 2, 2024

Implemented by

Smart Hydro Power GmbH (Ltd.)

Agriculture

December 2, 2024

Implemented by

Turbulent

Agriculture

January 22, 2024

Implemented by

Biro Air Energy Inc.

Agriculture

December 2, 2024

Implemented by

NTN Global

Agriculture

December 19, 2024

Implemented by

DesignPro Renewables

Agriculture

January 21, 2024

Implemented by

Mali Biocarburant SA

Agriculture

June 22, 2024

Implemented by

Mellowcabs (now MellowVans)

Agriculture

December 2, 2024

Implemented by

Mobile Hydro

Have thoughts on how we can improve?

Give Us Feedback