Agriculture

January 4, 2024

Promethean Rapid Milk Chiller

Read SolutionImplemented by

Promethean

Updated on February 26, 2024

·Created on July 5, 2016

The Biogas Milk Chiller provides off-grid biogas-powered milk cooling to smallholder dairy farmers without access to electricity.

The Biogas Milk Chiller provides off-grid biogas-powered milk cooling on-farm, allowing smallholder dairy farmers without access to electricity to store, deliver, and sell the highest possible quality of raw milk and increase their income. The Biogas Milk Chiller is capable of cooling between 2.5 and 10 Liters from 35ºC to 4ºC within 3 hours, meeting international standards.

Target SDGs

SDG 1: No Poverty

SDG 2: Zero Hunger

Target Users (Target Impact Group)

Household, Community

Distributors / Implementing Organizations

SimGas has partnered with BoPInc, Mueller and SNV on the Biogas Milk Chiller project. Organizations such as EEP, OFID, Powering agriculture, USAID, BMZ, Sida, OPIC, Duke Energy, Ideo.org and ASME are supporting the project.

Competitive Landscape

Direct competitors include Promethean Rapid Milk Chiller, EvaKuula, and Biogas Milk Chiller.

Regions

Africa

Countries

Kenya, Tanzania, Zambia

Manufacturing/Building Method

This product is currently in the prototyping phase and not yet manufactured at scale.

Intellectural Property Type

Patent

User Provision Model

The prototype can be acquired directly from the designer. SimGas Kenya plans to use crowdfunding, via the Lend-a-Hand crowdfunding platform, to give out loans to 170 farmers to buy biogas systems.

Distributions to Date Status

In 2015, SimGas completed testing of four working prototypes in two regions in Tanzania. They plan on distributing 50 more Biogas Milk Chillers to Tanzania, Zambia, and Kenya. SimGas claims to be equipped to provide 750 Biogas Milk Chillers to smallholder dairy farms in East Africa in 2018.

Storage capacity (L)

2.5-10

Time to cool (hr)

3-4

Cooling retention (hr)

14

Temperature control

Yes

Minimum internal temperature (°C)

4

Materials of construction

plastic molding

Protection from insect entry

Yes

Refrigeration cycle catalyst

Biogas

Design Specifications

The milk chiller is powered by biogas and has a cooling capacity between 2.5 and 10 L of milk. The chiller can cool milk from 35ºC to 7ºC within 4 hours. The chiller can receive biogas from any domestic anaerobic digester. The chiller uses absorption cooling technology, where heat from the biogas combustion is used to charge the system.

Technical Support

SimGas representative. Interview with representative.

Replacement Components

Unknown

Lifecycle

Unknown. However, this product comes with a 2 year warranty.

Manufacturer Specified Performance Parameters

Performance targets

Vetted Performance Status

SimGas’ R&D team tested 4 prototypes at 4 dairy farmers in Tanzania which demonstrated that the BMC complies with the international milk cooling standard: cooling raw milk down from 35 degrees Celsius to 4 degrees Celsius within 3 hours’ time.

Safety

Biogas is primarily composed of methane and carbon dioxide, which pose safety concerns if inhaled. Other safety concerns include explosion, asphyxiation, disease, and hydrogen sulfide poisoning.

Complementary Technical Systems

Simgas provides a variety of biogas systems that are fully integrated into farm solutions for rural households in developing countries.

Academic Research and References

Seybolt, E., Zhong, C., 2017. Design report on SimGas’ Biogas Milk Chiller: Challenges with applying sustainability and usability when developing for the East-African market from a small company in Europe. Kth Royal Institute of Technology, Stockholm, Sweden.

Edwin, M., Sekhar, S.J., 2015. Thermal performance of milk chilling units in remote villages working with the combination of biomass, biogas and solar energies. Energy, 91, pp. 842-851.

Edwin, M., Sekhar, S.J., 2014. Techno-economic studies on hybrid energy based cooling system for milk preservation in isolated regions. Energy conversion and management, 86, pp. 1023-1030.

Dijkink, B., Esveld, E., Broeze, J., Axmann, H., Vollebregt, M., 2019. Effects of milk cooling: A case study on milk supply chain for a factory in Ethiopia. CCAFS Working Paper No. 288, Wageningen, the Netherlands.

Compliance with regulations

Unknown

Other Information

Agriculture

January 4, 2024

Implemented by

Promethean

Agriculture

December 18, 2024

Implemented by

SimGas

Agriculture

January 28, 2024

Implemented by

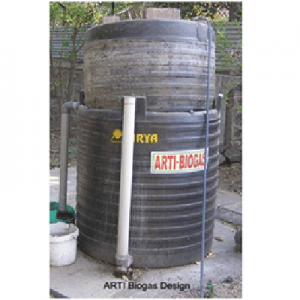

Appropriate Rural Technology Institute (ARTI)

Agriculture

May 27, 2024

Implemented by

Development Technology Workshop

Agriculture

December 17, 2024

Implemented by

Biogas International Limited

Agriculture

January 21, 2024

Implemented by

Mali Biocarburant SA

Agriculture

May 27, 2024

Implemented by

Montals Engineering

Agriculture

December 18, 2024

Implemented by

Tinytech Plants

Agriculture

December 19, 2024

Implemented by

Green Heat

Agriculture

February 24, 2024

Implemented by

Compatible Technology International

Have thoughts on how we can improve?

Give Us Feedback