Agriculture

January 24, 2024

Splash Stations

Read SolutionImplemented by

Splash

Updated on February 13, 2024

·Created on July 26, 2020

Agro-processing mills powered with solar energy.

The solar mills, developed and distributed by Village Infrastructure Angels (VIA), are milling systems powered by solar energy. The solar power milling stations are intended to work in off-grid rural communities, where agro-processors need to walk several miles to the nearest mill or have to process their produce by hand. The mills are provided by leasing, and women entrepreneurs are especially encouraged to run the solar agro-processing stations. The mills are monitored remotely via IoT technology to track energy consumption and charge the batteries.

Village Infrastructure Angels was founded in 2012 in the United Kingdom and currently operates in the UK, Australia, and Vanuatu.

Target SDGs

SDG 5: Gender Equality

SDG 7: Affordable and Clean Energy

Market Suggested Retail Price

$2,000.00

Target Users (Target Impact Group)

Household, Community

Distributors / Implementing Organizations

Competitive Landscape

Direct competitors include Solar Milling Small-Scale System.

Regions

Asia, North Pacific Area

Countries

Honduras, Indonesia, Papua New Guinea, Philippines, Vanuatu

Manufacturing/Building Method

This product is currently manufactured in China, through the company Project Support Services.Interview with Representative in 2020

Intellectural Property Type

Select Type

User Provision Model

Users can obtain this product directly from Village Angels Infrastructure. A 3-5 year leasing contract is signed by female entrepreneurs, which run the solar agro-processing power stations within the village. Solar-powered milling is provided to final clients through a pay-as-you-go system.

After delivery of the equipment, VIA provides local partners with training on how to install the renewable energy systems into rural villages, and local village operators and supply chain partners on technical aspects of the products, and business skills.

Distributions to Date Status

By 2017, more than 800 solar mills have been delivered, including 340 as cash sales and 270 on 3-5 year lease agreements.

Feedstock types

Rice, corn, flour, coconut, cassava

Feedstock rate (kg/hr)

20-50 kg/hr

Power source

Motorized

Energy requirement (W)

1,500-5,000 W

Portable or stationary

Portable

Design Specifications

The solar mills work using direct current at 24 V, driven directly from the photovoltaic modules without any current conversion stage. The solar milling system consists of a set of photovoltaic modules, batteries, and a charge controller. The system is monitored remotely via a SIM card provided by Eseye. The company offers seven kinds of solar mills developed by PSS, intended to different tasks: rice huller, corn sheller, flour grinder, or coconut/cassava grater.

Technical Support

Provided by VIA.

Replacement Components

The mills are designed such that the replacement components are available in local stores. When this is not possible, replacement components are provided by the manufacturer. Interview with Representative in 2020

Lifecycle

5 yearsInterview with Representative in 2020

Manufacturer Specified Performance Parameters

Village Infrastructure Angels has set the goal to serve with their products 1 million people by 2020.

The solar mills can reduce the time of the hand-processing of staple crops from 1 hour to 5 minutes. By mechanizing this task, usually performed by women, the time saved can be used to support children's education. In particular, girls are avoided to be pulled out of school to help with manual agro-processing.

Vetted Performance Status

None

Safety

Users should be aware to properly handle the electric components of the mills. Additionally, batteries should not be opened, and in case of failure or misfunctioning of one of its components, it is recommended to contact the provider.

Complementary Technical Systems

None

Academic Research and References

None

Compliance with regulations

None available for the solar mills.

Other Information

On this website, there can be found videos showing the performance of solar agro-processing stations.

Agriculture

January 24, 2024

Implemented by

Splash

Agriculture

January 12, 2024

Implemented by

VIP

Agriculture

September 18, 2024

Implemented by

Alvan Blanch

Agriculture

December 16, 2024

Implemented by

Renewit

Agriculture

December 10, 2024

Implemented by

Renewit

Agriculture

December 23, 2024

Implemented by

Guangzhou Anern Energy Technology Co., Ltd

Agriculture

January 19, 2024

Implemented by

Solar Street Lights Africa

Agriculture

December 17, 2024

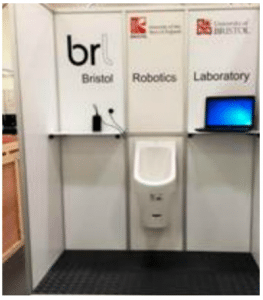

Implemented by

Bristol Robotics Laboratory

Agriculture

January 28, 2024

Implemented by

Fenix International

Agriculture

January 5, 2024

Implemented by

MeraGao Power

Have thoughts on how we can improve?

Give Us Feedback