Agriculture

August 21, 2024

Claphijo Enterprises Solar Dryer

Read SolutionImplemented by

Claphijo Enterprises

Updated on August 21, 2024

·Created on May 30, 2014

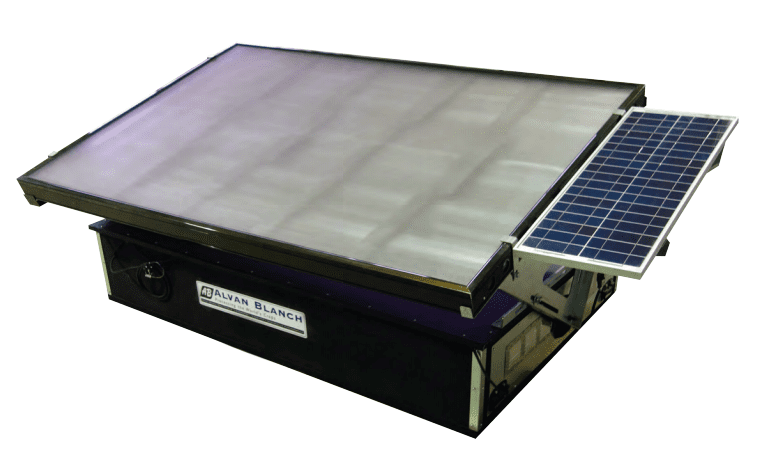

Solar Drier - Model SD 22-3 is a solar-powered food dehydration system that can dry a wide range of crops with little maintenance.

Solar Drier – Model SD 22-3 is a solar drier made up of a solar air heater, perforated stainless steel trays and four small fan units. It is suitable for drying various fruits and vegetables ideally, with a maximum slice thickness of 6 mm. It can be used to dry food products such as fruits, vegetables, seeds, filleted/deboned fish and others.

Target SDGs

SDG 2: Zero Hunger

Market Suggested Retail Price

$4,163.00

Market Suggested Retail Price (Secondary Currency)

3175

Target Users (Target Impact Group)

Household, Community, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

Alvan Blanch Development Company Ltd distributes the solar drier product worldwide

Competitive Landscape

Direct competitors include SunWorks Solar Food Dryer.

Regions

East Africa, West Africa

Manufacturing/Building Method

The Solar Dryer - Model SD 22-3 is customized to suit the requirements of the client. The main structure of the drier is made of mild steel painted Hammerite blue. The drier has stainless steel trays and a solar panel to help achieve drying evenly throughout the product.

Intellectural Property Type

Trademark

User Provision Model

Users can obtain the Solar Dryer - Model SD 22-3 directly from Alvan Blanch

Distributions to Date Status

Unknown

Drying capacity (lbs/m³)

0.067

Drying duration (hr)

1 – 72

Load capacity (m³)

1.19

Operating temperature range (°C)

Unknown

Temperature control

Yes

Number of trays

3

Materials of construction

Stainless steel

Design Specifications

The Solar Drier - Model SD 22-3 is made of mild steel painted Hammerite blue. It has fully adjustable inlet tray and outlet doors for temperature regulation and a translucent acrylic sheet. Solar collector tray is a 3mm mild steel painted black. The drier also has a chimney in spiral wound galvanised ducting and a woven screen for preventing insect entry.

To dry products, sunlight heats the black mild steel surface of the drier, which in turn radiates heat and produces convection currents. Hot air rises through the wet product in the stainless steel trays, and warm humid air exists through the exhaust chimney. The trays can be easily accessed through a door in the side of the drying chamber. The time it takes for the drier to achieve a dried food product is dependent on the initial moisture content in the food product, slice thickness and environmental conditions such as air relative humidity, sunshine hours and temperature. Hence, it may take 1 to 72 hours to achieve a desired dried food product.

Technical Support

A Nigerian technical team, based in Benin City, handles all customer support in Nigeria – as well as some of the maintenance work across Africa. Alvan Blanch also has a number of commissioning engineers in the UK who travel to clients worldwide.

Replacement Components

Replacement components are available with the initial purchase of the drier

Lifecycle

5-10 years

Manufacturer Specified Performance Parameters

The drier is designed to be economical to use and simple to operate and maintain.

Vetted Performance Status

Unknown

Safety

The potential hazard associated with the operation of this product include some burns.

Complementary Technical Systems

Unknown

Academic Research and References

Stiling, J., Li, S., Stroeve, P., Thompson, J., Mjawa, B., Kornbluth, K., and Barrett, D. M., 2012, Performance evaluation of an enhanced fruit solar dryer using concentrating panels. Energy for sustainable development, 16(2), pp 224-230.

Whitfield, D. E., 2000, Solar dryer systems and the internet: Important resources to improve food preparation. Proceedings of International Conference on Solar Cooking, Kimberly, SouthAfrica.

Leon, M. A., Kumar, S., and Bhattacharya, S. C., 2002, A comprehensive procedure for performance evaluation of solar food dryers. Renewable and Sustainable Energy Reviews, 6(4), pp 367-393.

Janjai, S., 2012, A greenhouse type solar dryer for small-scale dried food industries: development and dissemination. International journal of energy and environment, 3(3), pp 383-398.

Compliance with regulations

Unknown

Other Information

The Queens Award for Enterprise: International Trade 2012, state recognition by Buckingham Palace, winner of A.T. Ferrell Award for dealer innovation

Agriculture

August 21, 2024

Implemented by

Claphijo Enterprises

Agriculture

August 21, 2024

Implemented by

SAECSA

Agriculture

August 21, 2024

Implemented by

Science for Society

Agriculture

August 22, 2024

Implemented by

SunWorks

Agriculture

August 22, 2024

Implemented by

UC Davis D-Lab

Agriculture

January 19, 2024

Agriculture

December 10, 2024

Implemented by

Renewit

Agriculture

August 21, 2024

Implemented by

Marius Rossouw design engineer Aflastop

Agriculture

January 22, 2024

Implemented by

Sparky Social Enterprise Ltd.

Agriculture

February 5, 2024

Implemented by

Deploy Tech

Have thoughts on how we can improve?

Give Us Feedback