Agriculture

December 29, 2023

Pure Hydration Thirst Aid Station

Read SolutionImplemented by

Pure Hydration

Updated on February 20, 2024

·Created on May 23, 2016

UV sanitizer for medical tools.

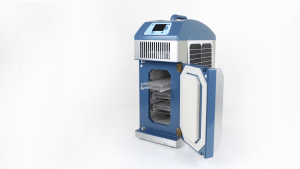

The Sterilux SteriBox and Control Station use ultraviolet light (UV) to sanitize metal and non-metal medical instruments. The sterilization process relies on the UV radiation to activate oxygen from air into ozone. After sterilization, the ozone is converted back to oxygen leaving no toxic residues.

Target SDGs

SDG 3: Good Health and Well-Being

Market Suggested Retail Price

$27,520.00

Target Users (Target Impact Group)

Small and Medium-sized Enterprises, Public Sector Agencies

Distributors / Implementing Organizations

SteriLux

Competitive Landscape

Direct competitors include Eniware Portable Sterilizer PS-25.

Regions

Africa

Countries

India

Manufacturing/Building Method

As of July 2016, the first 10 products are planned for manufacturing and distribution by the end of 2016. Interview with designer, July 2016

Intellectural Property Type

Patent

User Provision Model

Users can purchase this product directly from the manufacturer.

Distributions to Date Status

10+

Capacity (Liters)

30

Consumables

Blue indicator sticker, printed label.

Indispensable equipment for function (Y/N)

N

Maintenance or calibration required by user at time of use? (Y/N)

None known

Method of sterilization

Ultraviolet (UV) light

Power Supply Type

10 minutes of electricity per cycle, or battery power for up to 100 cycles

Water required

1mL of water per cycle

Weight (kg)

10.5

Design Specifications

The Control Station generates ultraviolet light (UV), which creates the sterilizing agent (ozone) from the oxygen present in the air. Software is included to execute the complete sterilization process. The SteriBox ensures the sterile barrier. This system needs 10 minutes of electricity/cycle or can be battery-powered for up to 100 cycles. Experts emphasize that a reliable source of power or electrical storage and/or backup power is required. 5 mL of drinkable or non-drinkable water is needed per cycle.

Control station design specifications: Dimensions: 40 cm x 30 cm x 45 cm 15.7 in x 11.8 in x 17.7 in Weight: 10 Kg, 22 lb Power: 100 W Voltage: 110 / 230 V Frequency: 50/60 Hz Battery life: 100 cycles Shelf life in number of cycle: 20,000 Capacity: 10 cycles per hour Wavelengths: 185 nm and 254 nm

SteriBox design specifications: Dimensions: 62 cm x 30 cm x 17 cm 24.4 in x 11.8 in x 6.7 in Bigger and Smaller boxes will also be made. Weight: 0.5 Kg, 1.10 lb Material: HDPE Capacity: 30 liters, 7.9 US gal lqd Storage maximal period: 3 months

Technical Support

Provided by the manufacturer.

Replacement Components

Batteries

Lifecycle

Control Station : 10,000 sterilization cycles or 5 years. SteriBox : 1,000 cycles or 3 years.Interview with designer, July 2016

Manufacturer Specified Performance Parameters

Manufacturer specified performance targets include low temperature, safety, cost-effective, and sustainable.

Vetted Performance Status

The SteriLux team tested the effectiveness of using ozone as a sterilizing agent for metal and non-metal medical equipment. Ozone levels ranging from 100 - 1 000 ppm (0.2-2 g/Nm3) were generated and several variables were studied. Survivor curves for the sterilization process were created. The study demonstrated the feasibility of using ozone to sterilize medical devices at room temperature.

Safety

Surgical equipment that is improperly sterilized may cause infection and other medical complications. The Sterilux website describes that no toxic components are created by the system because the product uses ambient air to temporarily induce ozone, but the gas is then destroyed and the air returns to its initial composition at the end of the sterilization cycle.

Complementary Technical Systems

The SteriBox and Control Station are complimentary systems. Other complimentary technical systems include consumables such as a blue indicator sticker and printed label.

Experts note that UV technology requires a source of UV (which may be difficult to access in remote areas as the availability of UV hardware is limited). Other components such as housings, covers, electronics and controls are available if an appropriate supply chain is developed and maintained to provide these materials at the appropriate cost, quality and delivery to support production. No special piping or chemicals are required to support UV sterilization.

Academic Research and References

S. A. Thill and M. Spaltenstein, Toward Efficient Low-Temperature Ozone Gas Sterilization of Medical Devices, Ozone Sci. Eng., Sep. 2019, doi: 10.1080/01919512.2019.1704217.

W. A. Rutala and D. J. Weber, Disinfection and sterilization in health care facilities: What clinicians need to know, Clinical Infectious Diseases, vol. 39, no. 5. Oxford Academic, pp. 702–709, 01-Sep-2004, doi: 10.1086/423182.

Compliance with regulations

ISO 13485, ISO 14937, ISO 11607, ISO 14161, ISO 11138, CE marking

Evaluation methods

The product and manufacturing has been evaluated in accordance to ISO 14937, ISO 11607, ISO 14161, ISO 11138.

Other Information

2nd Prize for the Best Poster Presentation Award at the 20th World Sterilization Congress.

Agriculture

December 29, 2023

Implemented by

Pure Hydration

Agriculture

December 10, 2024

Implemented by

Renewit

Agriculture

January 19, 2024

Implemented by

On the Spot Solutions

Agriculture

June 25, 2024

Implemented by

RootIO

Agriculture

January 9, 2024

Implemented by

Envirosan

Agriculture

June 28, 2024

Implemented by

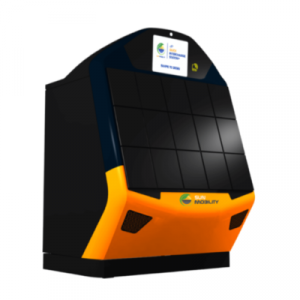

Sun Mobility

Agriculture

January 17, 2024

Implemented by

Philippine Army

Agriculture

February 20, 2024

Implemented by

Stone Cold Systems

Agriculture

December 14, 2023

Implemented by

AFRIpads

Agriculture

December 2, 2024

Implemented by

BioLite

Have thoughts on how we can improve?

Give Us Feedback

This is really helpful to have a list of articles that include relevant uses of this technology in developing countries.

Could you also provide a set of general documents about ultrasound & resource poor settings from trusted sources like WHO and UNICEF?

For instance:

WHO manual of diagnostic ultrasound: http://apps.who.int/iris/bi…

Also general article about uses of ultrasound across countries:

http://www.ncbi.nlm.nih.gov…

The other question I have is whether there is a place in the general references section for any discussions of misuse of a technology? This would help designers as well as donors ensure they don’t go down the wrong path.

For ultrasound the big story is gender selection. Here is the UN’s review of various aspects of gender selection as supported by ultrasound and amnio:

https://www.unfpa.org/sites…

Some excerpts:

“In five Asian and South Asian countries2 legal restrictions on the use of technology for sex selection purposes (either for sex determination or abortion) have been put in place over the past three decades. These restrictions have included laws that prohibit determination and disclosure of the sex of the fetus (except on medical grounds), those that prohibit abortion for sex-selection purposes and those that prohibit any advertising relating to prenatal sex determination.”

“An ultrasound examination has many appropriate medical uses, such as determining the age of the fetus, monitoring its healthy development and detecting abnormalities. Communicating the sex of the fetus can be done discretely, even silently, and prosecuting offenders is therefore practically impossible. Similarly, proving that a particular abortion was sex-selective is equally difficult. Following an ultrasound examination, women can go to a different clinic to have an abortion while providing a reason that is acceptable within the legal framework (Ganatra, 2008).”

———————–

Another source: cataloguing gender selection in India:

https://www.mcgill.ca/msr/f…

“However, advances in reproductive technology, in terms of the creation and availability of ultrasound machines, have corresponded with the move towards sex-selection and the increased elimination of female babies. In fact, Punjab, with the worst sex ratios in the country was the first state in 1979 to promote the commercial use of SD tests.”

As per Bob: The

users of this product are specified as “public Sectorâ€. It does not specify if training of the public

sector is required. Given that this product will require the loading of ampules

into their appropriate containers a minimum of clear user instructions are

required. Training processes and support

materials need to be made available for the public. Ongoing application and service support will

be required

Robert Hauck says:

Trained users imply that training processes and support materials will be made available. Ongoing application and service support will be required. Trainers will be required to develop user guides and training classes. This is especially important to ensure safe operation of this type of sterilizer technology.

Iana Aranda says:

As per Bob: reliable

source of power or electrical storage and/or backup power is required. This limits the application to where this

type of power is available. UV if

applied appropriately can be both a safe and effective means of

sterilization.