Agriculture

December 21, 2023

Afridev Hand Pump

Read SolutionImplemented by

SK Industries

Updated on January 31, 2024

·Created on October 3, 2020

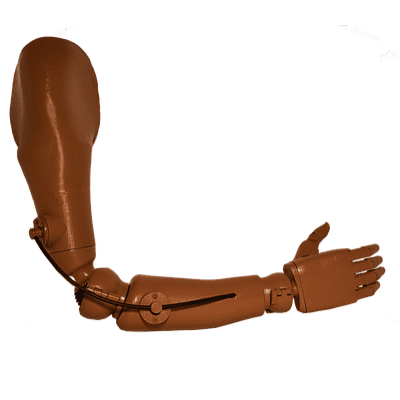

The Victoria Hand is a body-powered prosthesis consisting of a hand for amputee.

The Victoria Hand is a body-powered prosthesis consisting of a hand, a wrist, a limb-socket, and a harness. It has a natural appearance and is custom-made to fit each amputee. The hand allows the amputee to perform a range of activities needed. The Victoria Hand closes when activated into an adaptive grasp, allowing users to have a dynamic range of grip strength.

Target SDGs

SDG 3: Good Health and Well-Being

Market Suggested Retail Price

$240.00

Target Users (Target Impact Group)

Public Sector Agencies, NGOs

Distributors / Implementing Organizations

The Victoria Hand is distributed by these organizations: Range of Motion Project (Guatemala and Ecuador), Nepal Orthopaedic Hospital (Nepal), Agile (Cambodia), Enable International Haiti (Haiti), CoRSU (Uganda), St. Luke's Hospital (Kenya)

Competitive Landscape

Direct competitors include e-NABLE 3D-printed prosthetic devices and CURE Prosthetics.

Regions

Central Africa, Central Asia, Latin America

Countries

Cambodia, Ecuador, Egypt, Guatemala, Haiti, Kenya, Nepal, Uganda

Manufacturing/Building Method

Victoria Hands are manufactured at their clinics at Guatemala, Ecuador, Nepal, Cambodia, Haiti, Egypt, Uganda, and Kenya.

Intellectural Property Type

Trademark

User Provision Model

Users may purchase the Victoria Hand through one of the many distribution partners, through Range of Motion Project (Guatemala and Ecuador), Nepal Orthopaedic Hospital (Nepal), Agile (Cambodia), Enable International Haiti (Haiti), CoRSU (Uganda), St. Luke's Hospital (Kenya).

Distributions to Date Status

Over 120 Victoria Hand have been distributed as of 2019.

Craftsmanship required

3D printing

Patient satisfaction

Unknown

Patient compliance

Unknown

Comfort

Unknown

Materials

ABS Plastic (3D print material), silicone, steel (bolt & nut)

Water resistant (yes/no)

Yes

Amputation level

Trans-humeral and Trans-Radial

Weight (kg)

Unknown

Design Specifications

3D scanning is used to capture the unique shape of the individual’s limb, to thereby 3D print a customized socket for that user.

Full system solution includes: Hand, Wrist, Socket & Hardness

Silicone is used for fingertips to prevent slipping.

Rotatable Thumb: The thumb can be rotated by the user allowing it to hold various positions. This includes a one-finger pinch, a two-finger pinch, a power grasp, or a lateral grasp.

Backlock Mechanism: The voluntary close (VC) model contains the back-lock mechanism and allows the user to lock the hand closed, for tasks such as carrying bags, or constant grip onto objects.

Rotatable Wrist: The wrist contains a ball-and-socket mechanism that allows the user to quickly and easily change the orientation of the hand. This wrist can rotate the hand up to 360 degrees, while simultaneously being flexed or extended by 25 degrees.

Adaptive Grasp: The adaptive gripping mechanism makes it easier for your fingers to catch the shape of an oddly shaped object.

There are three different arm prosthesis currently available from the Victoria Hand Project:?

Trans-radial (mid-forearm)

Trans-radial suspension (short-forearm)

Trans-humeral (mid-humerus)

Technical Support

Provided by manufacturer

Replacement Components

None

Lifecycle

5 -10 years

Manufacturer Specified Performance Parameters

Designer specified performance targets include : low-cost, improve user's quality of life especially amputees in developing countries.

Vetted Performance Status

Unknown

Safety

Unknown

Complementary Technical Systems

None

Academic Research and References

Marino, M., Pattni, S., Greenberg, M., Miller, A., Hocker, E., Ritter, S., & Mehta, K., 2015, Access to prosthetic devices in developing countries: Pathways and challenges. In 2015 IEEE global humanitarian technology conference (GHTC), pp. 45-51.

Dechev, N., Cleghorn, W. L., & Naumann, S., 2001, Multiple finger, passive adaptive grasp prosthetic hand. Mechanism and machine theory, 36(10), pp. 1157-1173.

Massa, B., Roccella, S., Carrozza, M. C., & Dario, P., 2002, Design and development of an underactuated prosthetic hand. In Proceedings 2002 IEEE international conference on robotics and automation (Cat. No. 02CH37292), Vol. 4, pp. 3374-3379.

Dalley, S. A., Wiste, T. E., Withrow, T. J., & Goldfarb, M., 2009, Design of a multifunctional anthropomorphic prosthetic hand with extrinsic actuation. IEEE/ASME transactions on mechatronics, 14(6), pp. 699-706.

Millstein, S. G., Heger, H., & Hunter, G. A., 1986, Prosthetic use in adult upper limb amputees: a comparison of the body-powered and electrically powered prostheses. Prosthetics and orthotics international, 10(1),pp. 27-34.

Compliance with regulations

Unknown

Evaluation methods

Unknown

Other Information

None

Agriculture

December 21, 2023

Implemented by

SK Industries

Agriculture

December 27, 2023

Implemented by

SOVEMA

Agriculture

January 10, 2024

Implemented by

Tye WORKS

Agriculture

June 23, 2024

Implemented by

LoooP Creative Ltd

Agriculture

January 10, 2024

Implemented by

NRSRelief

Agriculture

December 31, 2023

Implemented by

Potential Energy

Agriculture

June 22, 2024

Implemented by

World Bicycle Relief

Agriculture

June 8, 2024

Implemented by

ClickMedix

Agriculture

February 14, 2024

Implemented by

USTAR Biotechnologies (Hangzhou) LTD

Agriculture

January 8, 2024

Implemented by

Gadgil Lab, University of California Berkeley

Have thoughts on how we can improve?

Give Us Feedback