Agriculture

February 29, 2024

Emergency Floor

Read SolutionImplemented by

Every Shelter

Updated on March 15, 2024

·Created on October 28, 2022

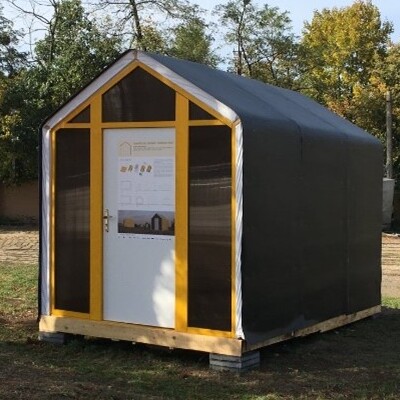

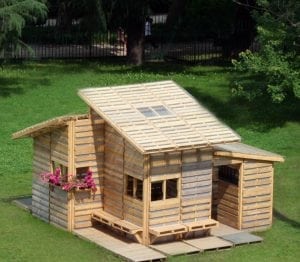

The Transportable Emergency Cardboard House (TECH_04) is an easy to assemble emergency cardboard shelter to provide improved temporary housing conditions.

TECH_04 is an easy to assemble emergency shelter designed by Archi-tektura.eu with the guidance of Prof. Mick Eekhout and eng. Agata Jasiołek and constructed in collaboration with students from Wroclaw University of Science and Technology. The housing design was motivated by the need to provide improved living conditions for the refugees, homeless population and communities displaced due to natural disasters or conflicts.

Target Users (Target Impact Group)

Distributors / Implementing Organizations

Manufacturing/Building Method

Prefabricated components such as cardboard Sandwiches on the roof and walls. The floor is made of wood materials.

Intellectural Property Type

Select Type

User Provision Model

The house is still under observation and monitoring to determine the structural stability, thermal performance and energy intensiveness and the information found does not specified user provision model.

Distributions to Date Status

None, this design is in its prototyping stages.

Intended number of occupants (#)

1 to 10 people depending on the number of connected shelters

Speed of assembly (h)

Number of hours from deployment to completion

Footprint area (m²)

13

Internal volume (m³)

Unknown

Material composition

Corrugated cardboard, Oriented Strandboards, Plywood

Lifespan (years)

1 to 5 years

Flammable flash point temperature (ºC)

Unknown

Maximum snow load (kg/m²)

Unknown

Maximum wind speed (km/h)

Unknown

Suitable climates

European countries

Design Specifications

The shelter is made from pre-fabricated components on the floor, wall and roof. The independent elements are assembled to generate a 13 m2 of floor space for the comfort and needs of the intended occupants.

Technical Support

According to the designers, the assembly can be done by non-technical professionals without any specialized equipment or tools for the work.

Replacement Components

Components are prefabricated and can be shipped for replacement incase it is damaged.

Lifecycle

1 to 5 years since it is meant to be an emergency shelter while temporary or permanent reconstruction solutions are being sought.

Manufacturer Specified Performance Parameters

EN-ISO 6946:2017 compliant U-values which provide a good thermal insulation. The wall has a thermal insulation capacity of 0.52 W/m2K while the roof and the floor have thermal insulation capacities of 0.54 W/m2K and 0.35 W/m2K respectively. The corrugated cardboard and honeycomb panels have a high insulation performance. The honeycomb panels should be at most 25mm thick to facilitate insulation through having the air pockets filled with air.

Vetted Performance Status

The shelter is under monitoring for the thermal performance, energy demand and intensiveness and structural durability by the Wroclaw University of Science and Technology designers and students involved in the project.

Safety

Easy to assemble requiring no professional skills or complicated tools. This guarantees the safety of the assembly process. Limited lifespan recommendation of up to 5 years to prevent collapse due to material deterioration from water or high humidity levels.

Complementary Technical Systems

None

Academic Research and References

Dominika J., Jerzy F. L., 2021, More than Just Another Book – Paper in Architecture. International Scientific Workshops. Innovative Structural Systems in Architecture

Latka J.F., 2019, Paper and cardboard as sustainable building materials, Structures and Architecture – Cruz (ed) pp 1163-1170

Latka, J. F, 2017, TECH. Transportable Emergency Cardboard House, Paper in Architecture, pp 402-468

Latka, J. F, 2016, TECH – Transportable Emergency Cardboard House, Timber Structures & Environmental Compatibility, pp. 1-9(9).

Compliance with regulations

EN-ISO 6946:2017 compliant. When dimensions are stabilized, the design performance will comply with the Polish, standards for residential buildings.

Other Information

None

Agriculture

February 29, 2024

Implemented by

Every Shelter

Agriculture

March 15, 2024

Agriculture

February 29, 2024

Agriculture

March 1, 2024

Agriculture

March 8, 2024

Agriculture

March 11, 2024

Agriculture

August 31, 2020

Agriculture

March 11, 2024

Agriculture

March 15, 2024

Have thoughts on how we can improve?

Give Us Feedback