Agriculture

January 4, 2024

Envirosan Eazi Flush

Read SolutionImplemented by

Envirosan

Updated on January 6, 2024

·Created on August 8, 2019

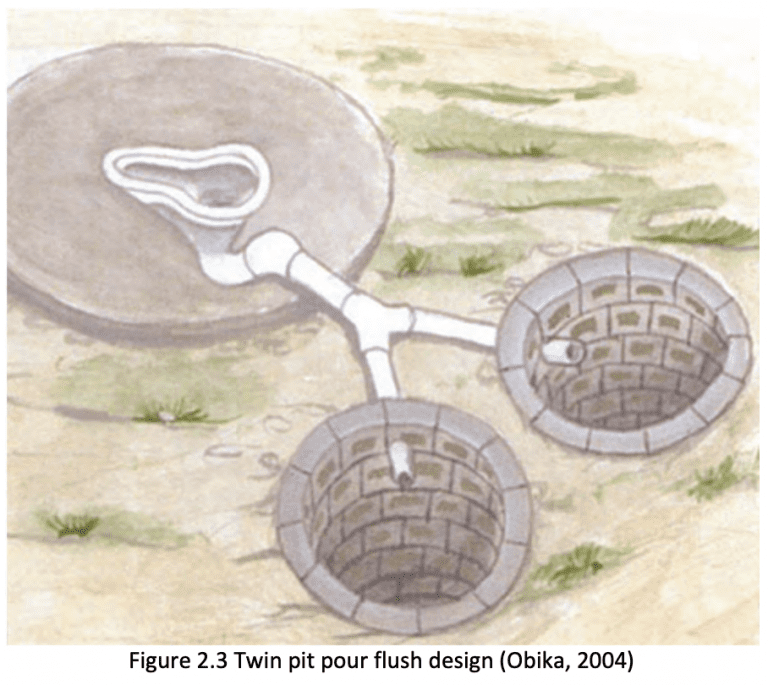

The Twin Pits for Pour Flush consists of two alternating pits connected to a pour flush toilet.

The Twin Pits for Pour Flush consists of two alternating pits connected to a pour flush toilet. The blackwater (and in some cases greywater) is collected in the pits, and this slowly infiltrates into the surrounding soil. Pits are used alternately, and over time (recommended two years) the solids are sufficiently dewatered and they can be manually removed with a shovel.

Target SDGs

SDG 6: Clean Water and Sanitation

Target Users (Target Impact Group)

Household, Community, Public Sector Agencies

Distributors / Implementing Organizations

Numerous organizations have implemented twin pits for pour flush, including Plan International, Sulabh International, WaterAid, and BRAC

Competitive Landscape

Direct competitors include DuraSan Latrine, Easy Latrine, Elephant Toilet, and Fossa Alterna.

Regions

Worldwide

Manufacturing/Building Method

This product is manufactured globally, typically using locally available resources and labor.

Intellectural Property Type

Open-source

User Provision Model

Local technicians, NGOs, and governments have provided twin pit pour flush latrines previously

Distributions to Date Status

Unknown

Toilet type

Pit latrine

Evacuation method

Pour flush

Storage conditions

Pit

Capacity (L)

Unknown

Time until emptying

Unknown

Design Specifications

The pit size depends on the number of users, but should be designed to allow for two years of accumulation, allowing the contents of the other full pit enough decomposition time to be manually evacuated.

To minimize the risk of cross-contamination, it is recommended that the twin pits be constructed 1 m apart from each other. They should also be constructed over 1 m from any structural foundation, and the full depth of the pit walls should be lined to prevent collapse and the top 30 cm should be fully mortared. These will help prevent infiltration and maintain the structure. For groundwater considerations, it is normally recommended to have a minimum horizontal distance of 30 m between a pit and a water source to limit contamination.

For the pit not in use, the idle pipe of the connecting junction should be closed or a straight pipe directly connected to the pour flush toilet.

Technical Support

Support provided by implementer or user

Replacement Components

Squat pan, pit emptying

Lifecycle

Depends on pit size and number of users. However, because the pits are used alternately, pit life is virtually unlimited (one is dewatered while the other is used, then the sludge can be removed).

Manufacturer Specified Performance Parameters

Performance targets include long lifespan due to the alternately used double pits, easier excavation than fecal sludge, pathogen reduction, possible use of stored fecal material as soil conditioner, reduced flies and odors compared to pits without a water seal, can be built and repaired with local materials, low construction and operating costs, and minimal land area required.

Vetted Performance Status

A physical, chemical, and microbiological analysis was conducted of pour-flush active and standing leach pits in South Africa. The pit filling rate was estimated to be 0.11 m3/y, and fecal sludge in active leach pits had similar ash, VS, CODT and TKN as other onsite technologies, but higher moisture content. The CODT in pour-flush sludge decreased 85% in 27 days in a laboratory test. Microbial DNA sequencing showed both aerobic and anaerobic degradation occurred in active and standing pits. Testing for local applicability, design, lifespan and user experience in South Africa showed successful implementation of pour flush systems over 18 months, with filling rates ranging from 114 L/yr to 392 L/yr, and easier sludge removal than VIP latrines. Testing in rural Bangladesh indicated household acceptance, excreta decomposition for soil fertilizer, but issues with durability of the bamboo superstructure used. An assessment was done in a settlement of the Idukki district in Kerala, India to understand the cost of open defecation and the return on investment of the twin pit pour-flush toilet. Based on the responses from 87% of the community, the rate of return was estimated as 160%.

Safety

The Twin Pit Pour Flush design is not suitable for areas with a high groundwater table or frequent flooding, or areas with clay or tightly packed soils. Health concerns include the leachate contaminating groundwater, stagnant water in pits promoting possible insect breeding, and pit failure or overflowing during floods.

Complementary Technical Systems

Water for pour flush

Academic Research and References

Hussain, F., et al., 2017, Advantages and limitations for users of double pit pour-flush latrines: a qualitative study in rural Bangladesh. BMC Public Health. Vol 7.

Byrne, A., et al., 2017, What happens inside a pour-flush pit? Insights from comprehensive characterization. Proceedings of the 40th WEDC International Conference, Loughborough, UK.

Bhadaran, R.S., et al., 2017, A tribal community-based discussion on economic repercussions of a twin-pit for pour-flush model toilet construction. IEEE Region 10 Humanitarian Technology Conference. pp. 878-882.

Still, D., Louton, B., 2012, Piloting and testing the pour flush latrine technology for its applicability in South Africa. Water Research Commission.

Tilley, E., et al., 2014, Compendium of Sanitation Systems and Technologies. International Water Association and EAWAG. 2ed.

Mara, D., et al., 2007, Selection of sustainable sanitation arrangements. Water Policy 9: 305-318.

Regional Water and Sanitation Group South Asia, 1992, Technical Guidelines on Twin Pit Pour Flush Latrines. Indian Ministry of Urban Development and the World Bank.

Katukiza, A.Y., et al., 2010, Selection of sustainable sanitation technologies for urban slums—A case of Bwaise III in Kampala, Uganda. Science of the Total Environment 409: 52-62.

Sherpa, A.M., et al., 2014, Vulnerability and adaptability of sanitation systems to climate change. Journal of Water and Climate Change 5: 487-495.

Mara, D.D., 2008, Sanitation now: what is good practice and what is poor practice? Proceedings of the IWA International Conference “Sanitation Challenge: New Sanitation and Models of Governance.” Wageningen University.

Cotton, A., 1995, On-plot sanitation in low-income urban communities: a review of the literature. WEDC, Loughborough University.

Mara, D.D., 1985, The design of pour-flush latrines. World Bank.

Compliance with regulations

Depends on national regulations, but meets standards for improved sanitation

Evaluation methods

N/A

Agriculture

January 4, 2024

Implemented by

Envirosan

Agriculture

December 20, 2023

Implemented by

Dry Flush

Agriculture

January 6, 2024

Implemented by

Sulabh International

Agriculture

June 23, 2024

Implemented by

Hans Hendrikse and Pieter Hendrisikse (Q Drum)

Agriculture

December 29, 2023

Implemented by

Folia Water

Agriculture

December 27, 2023

Implemented by

Shurflo Water Pumps

Agriculture

August 14, 2024

Implemented by

Spatap

Agriculture

January 5, 2024

Implemented by

TATA Swach

Agriculture

December 13, 2023

Implemented by

Yayasan Tirta Indonesia Mandiri

Agriculture

January 10, 2024

Implemented by

Tye WORKS

Have thoughts on how we can improve?

Give Us Feedback